ZH900 four-column horizontal type automatic machine Sand:

First, use

ZH900 type Sand is a new type of radio system 25 kg or less, high efficiency automatic sand core of hot-box core shooters. It is developed under the ZH600, ZH700 type based on the formula from the top core core shooting machine, which has a core and a shot from the core functions. Exit system applicable to horizontal classification of the sand core.

ZH900 type core shooting machine is suitable for mass production of a variety of complex sand core, sand core having accurate size, high productivity, low labor intensity.

ZH900 type core shooting machine using electric heating, temperature-controlled and equipped with the appropriate instrument.

Second, the main technical parameters

The maximum core box dimensions (length × width × height) 900 × 650 × 300

The maximum distance between the template 650mm

Clamping cylinder stroke 400mm

Clamping cylinder diameter φ125mm

Sand core maximum mass 25KG

Maximum capacity 200KG sand hopper

Heating power 30KW

Drive Pneumatic

Operation Manual / One Week

1, power supply 220V 50HZ

2, the system pressure 0.5 ~ 0.6Mpa

3, sand shooting pressure 0.3 ~ 0.45Mpa

4, the use of sand core phenolic resin coated sand

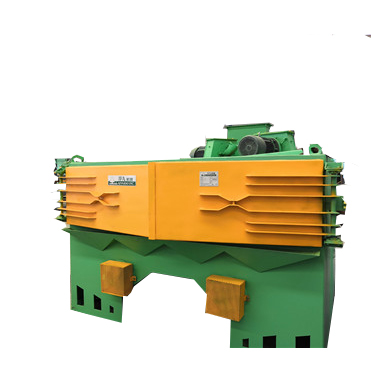

ZH1100 horizontal type core shooting machine

First, the main technical parameters

Template maximum size: 1100 × 920mm

The maximum distance between the template: 750mm

Clamping cylinder stroke: 400mm

Sand core Maximum weight: 45Kg

Plunger maximum drop distance 40mm

Shot of head movement distance 950mm

Coring method: manual

Operation: Auto / Manual

Sand mode: pneumatic conveying

Drive: Pneumatic

Power: AC380V

System pressure: 0.6 ~ 0.7Mpa

Sand shooting pressure: 0.1 ~ 0.4Mpa

Second, the host Overview

Host by the bed, column, beam components, mold components, sand bucket and other components. The bed is steel, welded steel plate, with sufficient strength and rigidity to ensure that all components work smoothly. Clamping cylinder, mounted on the bed inside the body, distribution box control button on the right side plate fixed bed.

Column using square steel and steel plate welded connection is a necessary component of the bed and the beam, while the gas bag, ensure instant shot of sand needed for a large flow of air.

The movable platen and four guide posts and guide the composition of the mold parts. Movable platen and the mold clamping cylinder coupled along four guide posts complete opening clamping process. When the movable die down place, four top core rod may top of the sand core, easy manual removal of the sand core.

When the beam member mounted above the machine. Clamping cylinder mounted on the beam and sand bucket, sand tube propulsion cylinder and other components. Transom gate underside of the unit, when the sand tube left, you can automatically open the gate for sand, make sand full automatic stop inflow of equipment for sand core making, by an automatic device for sand transport. .

Use automatic means of sand: sand automatic device is provided with a valve, closed when the air pressure, the barrel has a piston, loosen sand leaking into the barrel, the opening pressure, the piston is closed, pressure sand into the sand hopper preparations .

ZH850F automatic four-column vertical parting hot and cold dual core shooting machine

First, an overview of the host device and the action sequence

The aircraft from the bed member, composed of four-post frame mechanism, mold institution beam portion, the head portion shooting, strong electric part, the weak part, pneumatic part, the operative part. The machine has sufficient stiffness and strength, to ensure the stable operation of each part.

Mold member comprises left and right movable platen, the left and right bracket template, used to pass the guide shafts, bushings, high guiding precision, stable and reliable.

Sand cylinder (Plunger member) having a head shot of sand, another blow to the head amine, sand tube respectively by the cylinder drive completion shooting sand, blowing amine processes.

Four-column frame mechanism mounted above the clamping cylinder and head, the left is equipped with sand bucket, put sand gate. When sand tube sand then, push the gate open to begin quantitative fill sand, when removed, the shutter closes automatically complete the pressing cylinder pressed sand shooting and other processes.

The control part of Japan (OMQON) PLC programmable logic controller, motor control box connected to the host, strong electric part installed on the host after the middle of the column. Various solenoid valve mounted in the bed, to the overall appearance, the practical effect.

Second, the main technical parameters

The maximum mold size 780 × 440mm

Clamping stroke 400 mm

Sand hopper capacity 200KG

Heating Electric heating

Heating power 30KW

Main power AC380 / 50HZ

Operating Power AC220 / 50HZ

Drive Pneumatic

System pressure 0.55 ~ 0.7 Mpa

Sand shooting pressure 0.25 ~ 0.45 Mpa

Use sand phenolic resin-coated sand

Equipment Dimensions 2550 × 1550 × 2600 mm