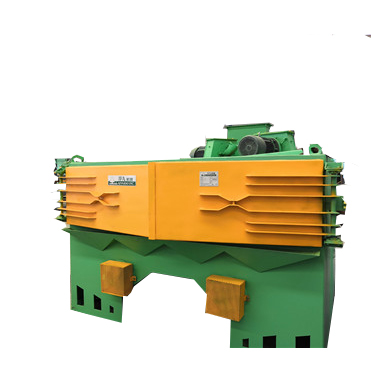

Z8616 Technical Case

Z8616BF hot-box core shooting machine is the equipment which adopt precoated sand to make sand cores. It can make the solid sand core within all kinds of template size and the maximum shoot sand weight. The machine involve two shoot head,it complete the straight line moving back and forth of shoot sand barrel to finish the movement of add sand and shoot sand. According to the different mould of user,two shoot head can both action and can run a single action at the same time, you can also placed two different moulds, and can put a pair of different mould for production,optimization design core box template installation, used three through type guide shaft and a half guide shaft, increase the stability of equipment,convenient coring and more human.All components of this equipment is automatic controled by PLC,convenient operation and high production efficiency. It adopts hot core box resin coated sand to ensure the quality of sand core.The way of the mold opening and closing is vertical parting, It can set the middle mold , left and right mold. Both side of the moving die have a set of process of cylinder, it can be installed separately two set of mould, it complete by movable mold clamping around.Open mold in place, run into the mandril, push out the sand core.

Part 2、The Main Technical Parameters

Moulding Size (L × W)760×460mm

Mould Maximum Size 730×480

Largest Sand Core Weight 25KG×2

Locking stroke 400mm

Clamping Force 29000N

Sand bucket capacity 200KG

Type Of Drive Air-operated

Operating Mode Manual/Automatic(single week)

Pneumatic System Pressure 0.55~0.6Mpa

Shoot Sand Pressure (Adjustable) 0.3~0.4 Mpa

Heating Method Electric Heating

Heating Power 25KW

General Power AC380V/50HZ Three-phase

Operational Power AC220V/50HZ

Sand Cores Used Phenolic Resin Coated Sand

Main configuration

1.The Clamping Cylinder QSC200×400 (2)

2.Walking Cylinder SC63×900TC-S

TC(Forward)220 (2)

3.Hold-down Cylinder Double Rod flange SC160×100 (2)

4. Gas control valves K22JK-20W (manual) (1)

5. Gas control valves K23JK-20W (automatic) (1)

6. Electromagnetic gas control valves K23JD-25W (automatic) (2)

7. FRL AC4000-04 (1)

8. A single joint member AW5000-10 (2)

9. The solenoid valve DS2542-8 (1)

10. A solenoid valve DS2542-15 (2)

11. The solenoid valve DS2543-15 (4)

12. PLC CPM1A-40CDR-A (1)

13. Switching power supply S-100-24 (1)

14. The relay JSS48A (3)

15. A temperature controller XMTD-2001 (4)

16. The proximity switch HL-S20-N8N0 (6)

|

Part 5、Failure Analysis And Solution |

|

|

Fault Phenomenon |

Reason |

Elimination Methods |

|

Power light and PC indicator light are not bright |

No power or circuit breaker disconnect |

Check the power supply and circuit breakers,try again,If it disconnect again,you should check ,then open the switch after troubleshooting. |

|

|

|

|

|

Pressure head and shoot barrel junction surface sandblasting |

Pressure head sealing rubber ring is damaged |

Replace the rubber ring. |

|

Shot barrel not forward |

No pressure: or shoot cylinder position only inappropriate position of the switch |

Open source: adjust the shot cylinder to loosen close state |

|

Shoot head pressure abnormal |

Inappropriate position of barrel forward to close to the switch |

Adjust the shot cylinder forward close to the switch. |

|

Shoot sand abnormal |

Inappropriate position of proximity switch of shoot head pressure ,or shoot sand time improper adjustment |

Check the location close to the switch:adjust the time of shoot sand |

|

No automatic |

Inappropriate position of proximity switch of shoot barrel forward and backward and shoot head pressure, or improper selection of control switch |

Check the location close to the switch:check whether the control switch in the automatic position. |

|

temperature controller abnormal |

thermo-couple wire not connection or improper connection; Improper temperature setting, probe model is discrepancy with the instrument |

Properly connected thermo-couple wire :adjust the set temperature in the range of normal function or change the probe which discrepancy with the instrument |

|

The sand ejected when the shot barrel lift |

Exhaust time is too short ;or exhaust valve is damage |

Check and change the exhaust valve;Clean up the dust in the exhaust funnel |

|

There is no sand in the shot barrel |

The entrance of storage sand bucket is jammed by explosion bag |

Open gate to observe, Clear the blockage |

|

The entrance quicksand |

Sand gate jammed, and spring cannot be reset |

Clean the dirt in the sand gate rail to make sand gate move |

Attachment:

●Sand shooting pressure regulator

Shoot sand pressure is commonly in range of 0.02 0.04 Mpa (0.2-0.4 kg/cm2) .The operator can choose the right shoot sand pressure according to the characteristics of the sand core, the higher of pressure is not the better. High pressure can lead to sand mold cavity flow turbulence,influence filling effect,and easy to damage the mould.By adjusting the pressure reducing valve of shot sand into the air bag,you can adjust the shoot sand pressure.

●Reason and solution of insufficient of shoot sand or partial loose:

Poor exhaust.Strengthen exhaust,install the venting plug or Open vent groove at the appropriate.More exhaust is not the better,exhaust too much will cause partial loose.

Multi-cavity mold mutual interference between each cavity.Between the two cavity open trench and drill hole and exhaust.

Shoot sand pressure and shoot sand time is not appropriate.Adjust the shoot sand pressure and shoot sand time.

●The adjustment of the mold temperature:

Mould heating temperature on the temperature controller set according to the requirements of process.Depending on the mould generally in the range of 190-230 ℃,High temperature can cause charred on the outside and tender on the inside of the sand core. Low temperature will affect the production efficiency.Attention!Because of the difference of temperature measuring point temperature controller shows the actual temperature of the temperature is not necessarily of the mold.It should adjust the temperature according to the color of the sand core.

●Shoot sand time adjustment

Use the time relay on the control cabinet to adjust.The shoot sand time is longer which sand core with a large quantity of sand,The shoot sand time is shorter which sand core with a small quantity of sand.

|

ADD: |

No. 29, Shanghai West Road, Jiaonan, Qingdao, China |

|

TEL: |

400-1177-399 TM:1154609900/1154609966 |

|

After sales service: |

15005326709 spare parts:13608971655 |

|

FAX: |

86-0532-85136011 、0532-83975199 |

|

EMAIL: |

zhuzaojixie@126.com |

|

Internet:

技术论坛: |

www.qingdaoqingzhu.com En:www.qingdaofoundrymachine.com bbs.qingdaoqingzhu.com |

|

QINGDAO KNNJOO MACHINE INC. |