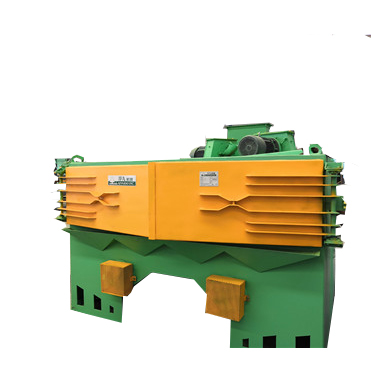

ZJ015S double rotary table shot blasting machine is a special shot blasting strengthening equipment which used to cleaning forging, casting and gear. it can shot blast on the steel and casting parts in original state, removal the rust, welding slag and oxide scale, and thus obtain uniform metallic luster, in order to improve the quality of finishing and fatigue strength of steel. To ensure that the workpiece of your company is cleaning accroding to the strict requirements, we use the following key technologies and measures to ensure that the machine and program design:

Blast wheel arrangement: due to larger handling capacity, high-efficiency blast wheel is arranged on the top or side, shot blasting is complement with each other, resulting in uniform cleaning effect.

Closed sealing mechanism, it is consist of wear resistant alloy plate and labyrinth seals and other components, changing the phenomenon whcih the steel shot get out of the chamber when shot blasting.

hot zone of shot blasting chamber use rolling Mn13 advanced guard, this material has great density and high hardness, service life is more than three times than the cast steel guard plate, and is more than six times than 65Mn guard plate, seamless coverage, easy to replace. And take advantage of the rebound of the projectile formation of secondary cleanup.

It can determine the number of open blast wheel according to the size of the workpiece, thus reducing unnecessary energy waste, while reducing the unnecessary broken of the equipment.

Shot supply shystem use special air control value and workpiece photoelectric detection, it is more stable and reliable than the traditional cylinder.

Elevator use anti-reverse ratchet pawl mechanism design: to prevent damage to the lift bucket elevator due to experience a sudden power failure or unexpected downtime bucket elevator with equipment caused by the reversal. At the same time it has lost passive rotation detection alarm device at the wheel.

Separator full screen curtain flow design: variable pitch change pitch automatically adjust the flow separator screen according to the projectile, the curtain stream reach full screen effect.

Shot Blasting: use WHEELBRATER hurricane turbine technology to produce high speed blast wheel, abrasion resistance is increased 60%, 50% reduction in maintenance costs. Special distributor structure maximize the utilization to 98%, the ordinary blast wheel is only 80%, in the mainland, the technologically is most advanced. Blast wheel linear arrangement, angle is made by three-dimensional simulation, projectile coverage consistent uniform.

Projectile purification cycle: use the most advanced overflow induction real full multi-stage curtain air separation unit, use special polyester core elevator belts, and remote control projectile controller, projectile circulatory system of each power set point failure alarm.

Dust removal system use second level dust removal: settling chamber+ cartridge dust collector, the second stage may be a pulse blowback cartridge dust collector or pulse bag dust collector, dust emission concentration is less than 50 mg / m3.

ZJ015 type shot blasting machine is a horizontal type rotary shot blasting equipment, it is consist of shot blasting chamber, turntable drive system, turntable protection, blast wheel, projectile circulation purification system, projectile recovery system, dust removal system and electrical control system.

shot blasting chamber structure: The machine is mainly composed of the chamber, turntable, transmission, separator, elevator, transport shot means, blast wheel and other components, in the top and sides of chamber have high-speed rotating blast wheel, it has the best shot blasting position of the workpiece, workpiece turn out from the chamber with turntable, cleaning effect can be seen directly, in order to carry out the next step. Projectile principle: shot blasting machine adopts the principle of transverse projectile, the axis of blast wheel get right angle with the workpiece traveling direction, produce the best impact effect, prevent the empty projectiles thrown and affect the cleaning effect.

Shot blasting chamber features: steel plate welded structure, with sufficient strength and rigidity. The installation direction of chamber and blast wheel is design by three-dimensional and dynamic simulation, so it can ensure the good effect of workpiece cleaning and make maximize the effectiveness of the device, the main shot blasting zone use ??high manganese protective shield, this shield has a high impact toughness, and it can make full use of the kinetic energy of the projectile, it is continue to hit the surface of workpiece effectively, it will help improve the quality of cleaning quality and cleaning efficiency. Turntable placed high wear-resistant perforated sheeting to prevent large lumps and flash, burrs into the hopper, screw conveyor and elevator, to ensure the normal circulation of the projectile and devices work properly. Between shot blasting chamber and blast wheel is connected with the high-damping rubber pads, reduces shot blasting vibration and noise, improve blast wheel life. It has multilayer staggered rubber seal, which means sealed tight; Due to the ventilation of dust collector fan, it has some negative pressure in the chamber, no dust to escape.

Shot blasting chamber protection:

Features 1:Austenitic alloy steel plate rolling Mn13 life is generally six times than the traditional cast iron sheeting and 65Mn guard plate, three times than wear-resistant steel Mn13, and it is up to 12,000 hours -15 000 hours