1.Strip materials and product conditions

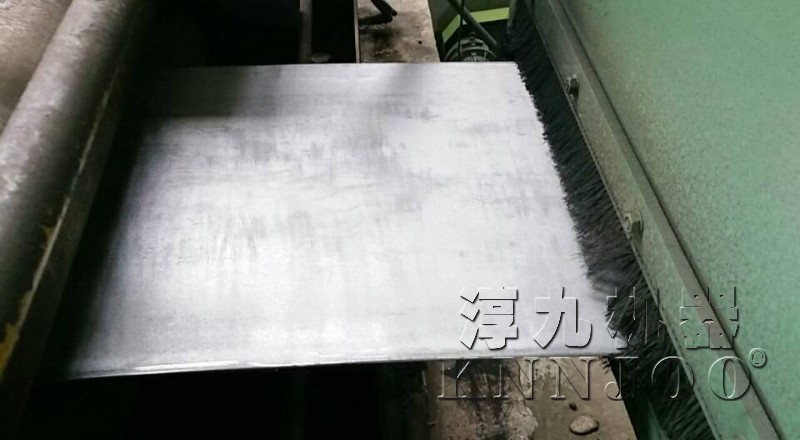

1.1 Steel strip type: Q235A/B

1.2 Coil status:

Strip thickness: 3.0 ~13.0mm

Strip width: 1000 ~20 00mm

Strip temperature: room temperature

1.3 Raw materials: From the hot-rolled coil

2 Capacity

2.1 Production capacity

20~100m/min

3 Common media conditions

..1 Power supply system

• power supply: 380VAC,- 10% ~+ 15% ; 50Hz±1Hz

• Operate the power supply: 220VAC, 24VDC

• Solenoid valve power:DC24V

3.2 Compressed air

Dry oil-free compressed air, pressure: 0.5~0.6Mpa

Consumption: 15 m3/min

4 Plant conditions

The maximum height of main shot

Blasting unit: <8.5m

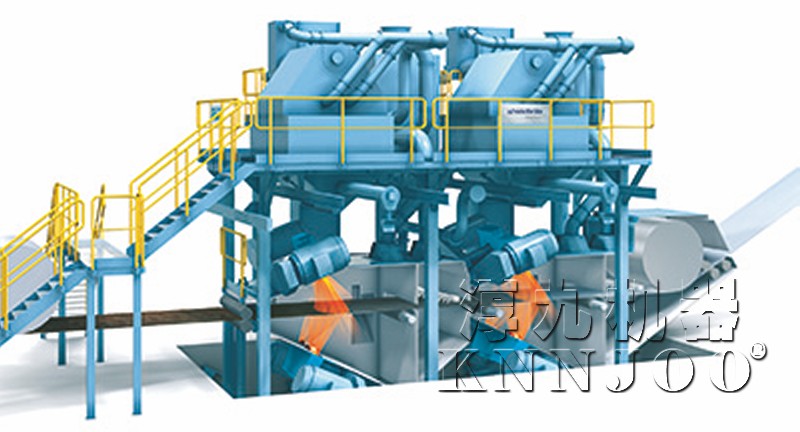

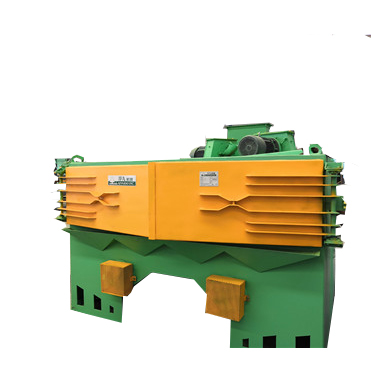

5.Main configuration of equipment

Shot blasting system, abrasive circulation system, motor and testing control components, dust removal system and so on.

6. The basic function of equipment and technical requirements

Shot blasting machine basic functional requirements

• After shot blasting steel strip surface can reach Sa2.5, surface roughness Ra ≤ 2.5μm.

Dust emission standards≤ 50mg / m3

The machine has a set of backup unit, easy to use equipment maintenance.

Dust removal system using the bag form.