- Home

- About us

- News Center

- Products

- Tunnel Type Blasting

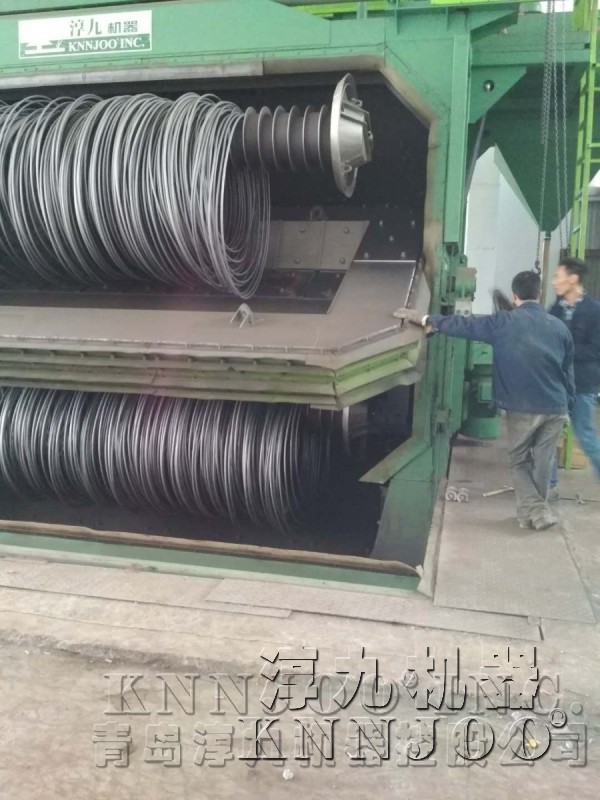

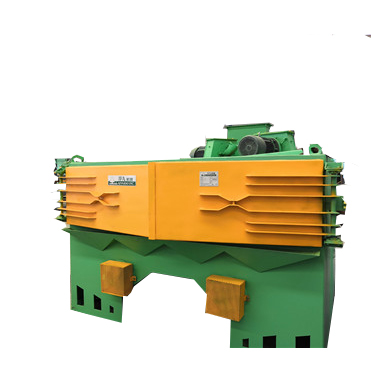

- Steel Bar,Coil Wire Rod

- Tumble Blasting

- Drum Type Blasting

- Hook Type Shot Blasting

- Mesh Belt Conveyor

- Turntable Blasting

- Pipe Blasting Machine

- Manipulator Type Shot Blast Sy

- Etching Strengthener

- Portable Type Blasting

- Blast Wheel,Spare Parts

- Sand Blasting Pot

- Shot Peening Machine

- Sandblasting Chamber

- Foundry Machinery

- Dust collector

- Service

- Video Center

- Contact Us